Setting up a new Lean assembly line?

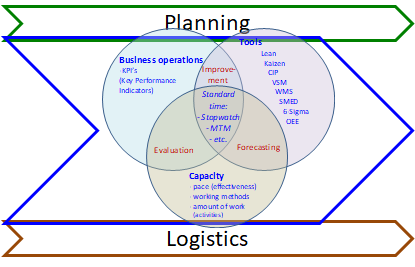

A new product? Expansion with an extra line? Or moving a production process to another hall or location? Just three reasons for a new assembly line. That will be planning and setting up. This influences the creation of a new or different layout. Not only the layout and interfaces are important, but also the product flow. Then again, it doesn’t stop there! The number of staff, standard times and logistic movements also need to be optimally organised. In short, the expertise of AQM International Consulting offers support.

Applied technics in organisation structure:

- Objective and start date

- or feasibility study

- or start setting up a production line

- Define processing steps

- Valuation of standard times

- Methods-Time Measurement (MTM)

- Value Stream Mapping (VSM)

- Layout (location space)

- Takting and balancing

- Staffing

- Logistical storage and outbound storage

- Set up

- Tools and workplaces (NB. electricity and compressed air)

- Recruitment and training of personnel

- Means of transport

Result:

- Optimal capacity utilisation,

- Good relation between

results and sacrifices, - Costs and benefits perception,

- Optimal lay-out and flow,

- Reliable planning,.

Cases

| Feasibility study | New production line |

| STARTING SITUATION | STARTING SITUATION |

| The customer initially wanted to increase the output by 60%. In order to continue to meet the demand. The parent company demanded that the growth had to take place within the existing walls. So, the assignment was to carry out a feasibility study. In order to map out whether this is possible: o double the output o in the existing assembly hall Time for a redirected production line? | The customer initially wanted to increase the output by 60%. In order to continue to meet the demand. The parent company demanded that the growth had to take place within the existing walls. The assignment was to carry out a feasibility study. In order to map out whether this is possible: o double the output o in the existing assembly hall Time for a different production line? |

|  |

| SELECTED APPROACH | SELECTED APPROACH |

| To read more, click here. | To read more, click here. |

Starting a new assembly line? Exciting?

It is always exciting to set up a new production line or production hall, which has to be Lean and efficient. A lot of things have to be thought about even before a start can be made. A deadline also has to be met. That is why agreements have to be made and kept. A pragmatic and project-based approach is pleasant and practical. Only that is often at the expense of their own capacity, because of the additional activities. That is why it is worth considering outsourcing. By choosing a good external solution, with experience. In other words, hand over the coaching and elaboration with peace of mind. But, by whom? AQM International Consulting has a lot of experience to offer. In what way? Just contact us. In short, you’ll see, we take away a lot of the excitement.