Services of AQM International Consulting

Every organisation deserves a pragmatic approach. Our first service or step is to record the current situation. Basis for the search for ideal solutions. In a project-based approach, our services offer a suitcase full of experience and methodologies. In order to come to a good solution choice step by step and together. After choosing the best solution, by the client, AQM International Consulting offers additional services. Such as implementing the solution.

Part of the services offered is also our strength. Involving employees in the project. Cooperation and involvement contributes to growth and continuity.

Another starting point in the provision of our services is after-check. Does the end result meet expectations and agreements? This usually follows a few months after the end of the project.

TWO Important and challenging questions above all are:

“Are we doing the work right”

“Are we doing the right work”

Our services can be divided into the following 3 services:

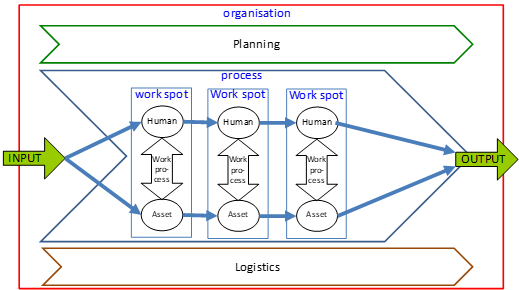

More capacity due to processoptimisation?

Does your organization think there is a lack of production capacity? For this purpose we offer our first service. In many cases there is still space to be used. Room for improvement of the production environment. After some time you don’t see this anymore. The so-called corporate blindness. Time to intervene?

Employess more productive by workplace optimisation?

A good second service is productivity with workplace improvement. Searching for the answer to the question: What is the productivity in your company? Expressed as a percentage of the output and performance. How effective is the effort, measured in a human-friendly way. Do you want to know the productivity?

Setting up a new Lean assembly line?

A specialist service that we offer finds its basis in development. Your company has a new product? Expansion with an extra assembly line is necessary. Your organisation is faced with a choice. E.g. whether or not to move a production process to another hall or another location? Reasons to set up a new assembly line?