Continue the pre-Assembly or outsource it

STARTING SITUATION:

The producer was faced with the choice: continue the pre-assembly activity or outsource this work. The factory had been pre-assembling itself for years. The employees themselves had already taken measures more often in order to become more productive. In order to maintain the work in the plant, a study was needed to increase workplace optimisation. The basic question also revealed that the MTM standard times also needed to be revised. Now, a better combination does not exist. Because every change is immediately measurable. Areas, number of employees and savings follow from the analysis.

CHOSEN APPROACH:

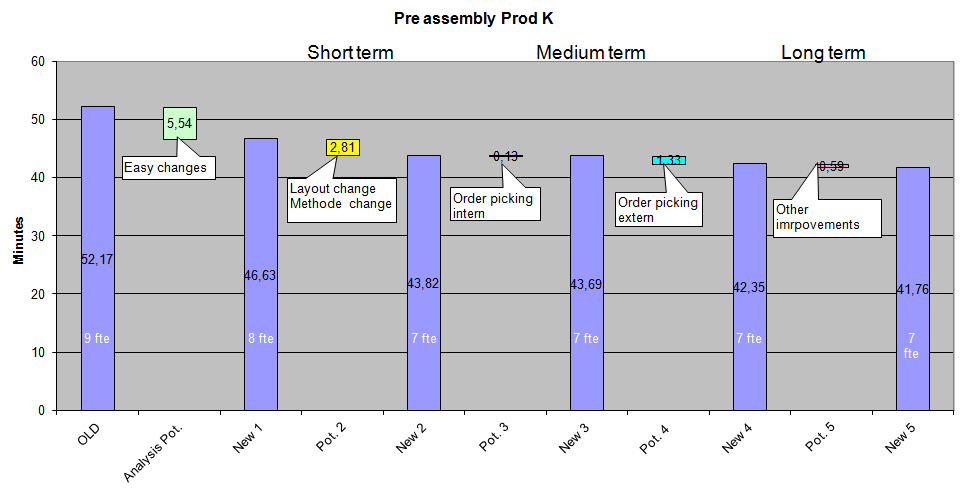

Firstly all the existing standard times were updated. In parallel, the layout of the departments, tools, and the supply and goods delivery were examined. Paths are shown by spaghetti-diagrams. By classifying potential improvements in a short, medium and long term, the benefit per phase became

clear (with investments, change of methods, etc.). Together with Logistics ABC-delivery has been chosen, to reduce the m2 and thereby shorten paths.

During the creation of a matrix, with all recommendations per phase, a chart is also coupled. With that, all savings per phase become visually clear. This helps the management make choices and implementation easy.

Before the implementation, the analysis and improvement proposals are discussed with representative employees, which increases acceptance.

RESULTS:

The pre-Assembly department is kept at the factory. By updating the standard times, small method adaptations and small investments, the number of full-time employees could be reduced from 9 to 7. Also through steady delivery of source materials, shortened transport and walk paths. An additional advantage is that the delivery to the assembly line is in sequence from now on.